PI: B. Andrawes/Student: M. Sung

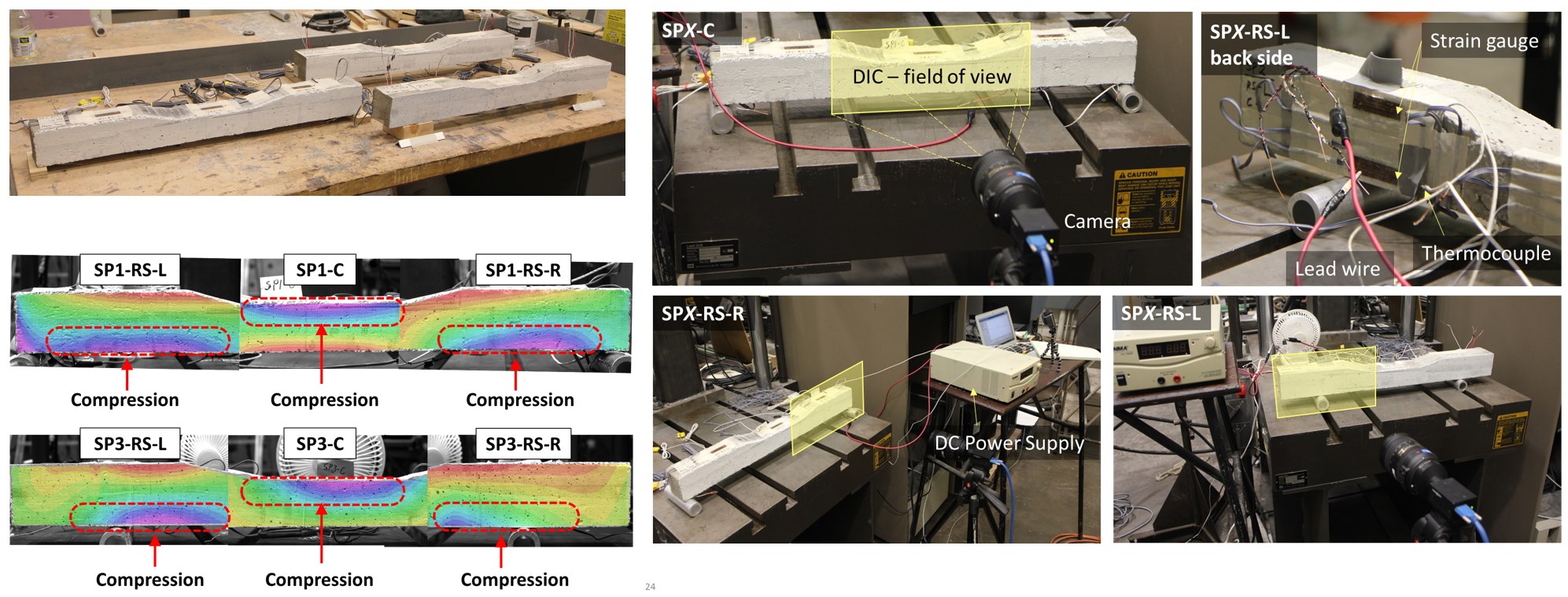

This project focused on developing an Adaptive Prestressing System (APS) for concrete crossties. The new prestressing system utilizes a unique characteristic of a class of smart materials known as Shape Memory Alloys (SMAs). Through heating, a SMA can recover its original shape after being excessively deformed beyond its elastic range. This shape memory phenomenon of SMAs can be used as a mean for prestressing concrete by embedding prestrained SMA wires in the concrete. When heated, the SMA will attempt to shrink inducing large recovery stress within the SMA that will in turn transfer to the surrounding concrete in the form of prestressing force. NiTiNb SMA were used in this study to prestress concrete crossties in the form of APS. APS can be described as a fuse made of SMA wires connected to steel wires in series. The APS is utilized to apply prestress only at target regions in the crosstie. The research work comprised three main phases: (1) validating local prestressing using SMA wires only, (2) developing the APS, and (3) structural testing of concrete crossties using APS. First, to validate the use of SMA as prestressing material in concrete, 2mm diameter NiTiNb SMA wires were used as prestressing reinforcement in small-scale 30 in. long concrete crosstie specimens. Three small scale concrete crosstie specimens were designed with different SMA prestressing system configurations, namely, straight, L-shaped, and U-shaped. Digital Image Correlation (DIC) and strain gauges were used to capture strain distribution within the ties during prestressing. The test results showed that SMA was able to apply prestressing force locally in the crossties at the intended locations. The second phase of the project focused on the design and development of APS for crosstie prestressing. An APS consists of steel and SMA wires connected mechanically in series to act as a prestressing reinforcement in the tie. When the SMA wire in the APS (named fuse) is activated, i.e. heated, recovery stress generates in SMA transferring through the connection to the steel wires. In this application, SMA fuse is used as mechanism through which steel wires are easily stressed without the need for conventional hydraulic jacking/stressing. To validate the new concept, a 1/2-scale concrete crosstie prestressed with the new APS was tested. The tests proved the success of the proposed APS in applying prestress to a targeted region in the crosstie.

Comments are closed