Nathaniel Levine, Dr. Brian Eick, and Dr. Billie F. Spencer recently completed the testing an anchorage assembly embedded in concrete as part of a nationwide project studying fatigue of miter gates. The goal is to work with the US Army Corps of Engineers (USACE) to develop a methodology to monitor their large inventory of miter gates on the Mississippi, Ohio, and other rivers to better estimate where and when fatigue failures are likely to occur and to take remedial action before catastrophic failure.

USACE is currently in the process of upgrading miter gates on the Upper Mississippi River. Miter gates are a component of river lock systems that seal the ends of the lock chamber so that the water level can be raised or lowered. Of particular concern is the miter gate anchorage, which transfers the overturning reaction from the hanging gate to the concrete lock wall. The anchorage is a steel frame partially embedded in the concrete lock wall.

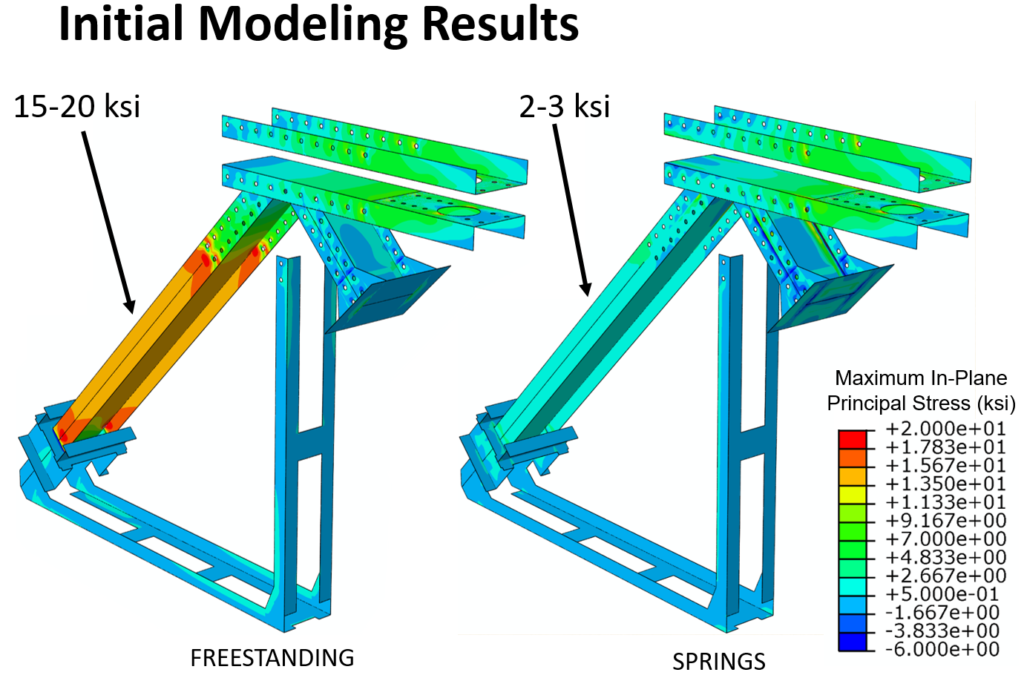

When anchorages are designed, the contribution of the concrete is typically neglected and the anchorage is analyzed like a freestanding truss. This approach predicts very high stresses in the anchorage – high enough that design engineers are worried about imminent fatigue failures in the embedded components. This concern is compounded by the fact that gates on the Upper Mississippi River are being replaced with new, heavier gates so the anchorage loads will increase. Given all these factors, USACE has been excavating and replacing the anchorages as they upgrade the gates on each lock.

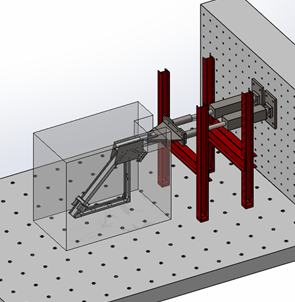

However, this analysis method is conservative and a more accurate analytical model could eliminate these fatigue concerns. The goal with this project was to develop a better way to analyze the anchorage and then perform full scale testing to calibrate and verify that model. Mr. Levine, Dr. Eick, and Dr. Spencer have proposed a new way to analyze the anchorages, modeling the concrete as springs perpendicular to all steel surfaces. This approach captures the effect of steel bearing against concrete but conservatively neglects any bond or friction between the steel and concrete. This modeling predicted much lower stresses in the steel than the USACE traditional analysis method and suggests that there is no need to excavate and replace the existing embedded anchorages.

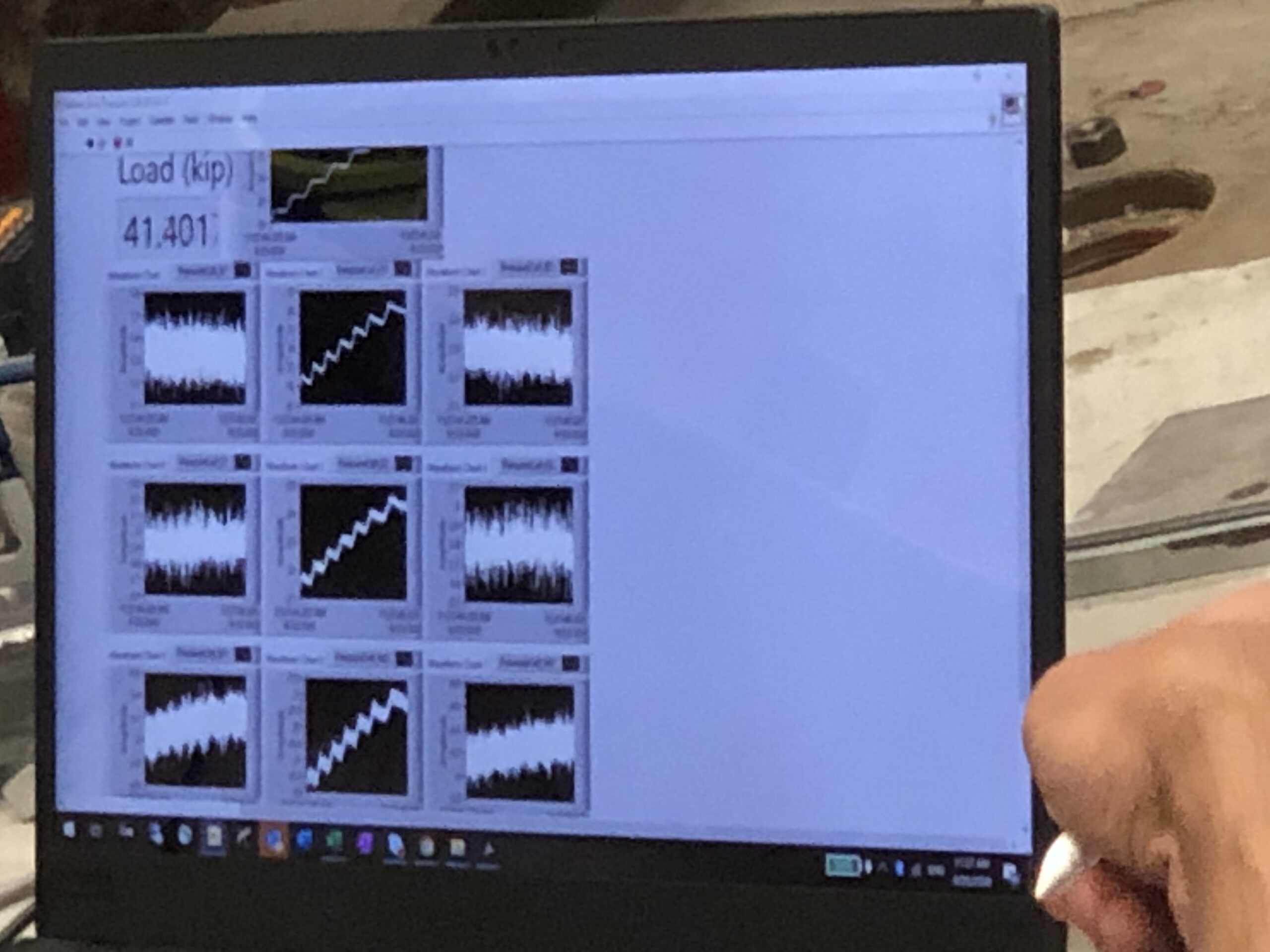

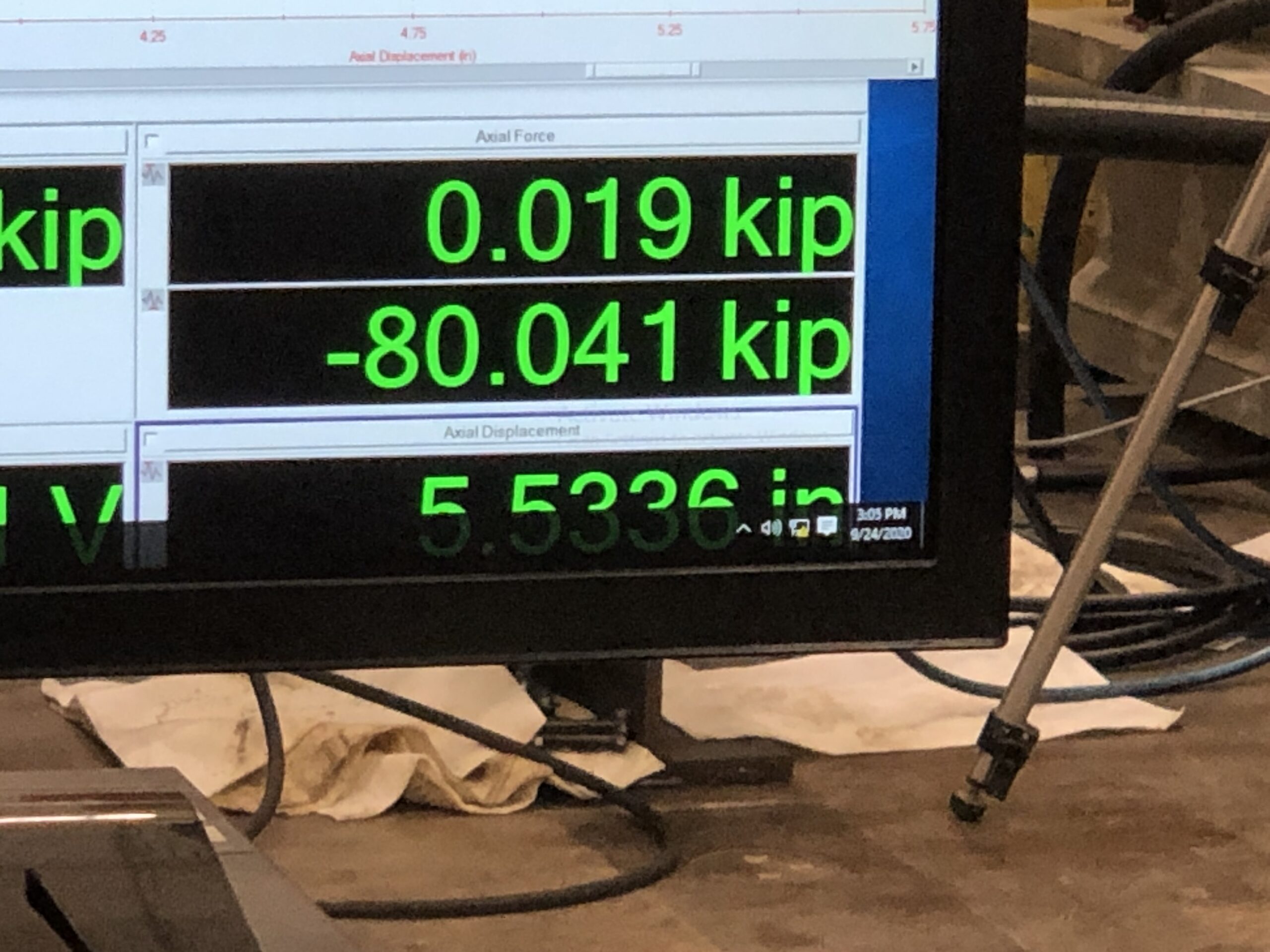

The USACE will not base a multi-million dollar design decision off an unverified model so the research group at UIUC worked with the NSEL Machine Shop to build a full-scale model of the anchorage. They first tested the steel alone to mimic the “freestanding” condition of the typical anchorage analysis. They then cast the specimen in a concrete block and repeated the test. The results confirmed the finite element modeling – the stress deep in the embedded components is sufficiently low that fatigue is not a concern and USACE can likely reduce the scope of their anchorage replacement efforts, potentially saving millions of dollars. Some exposed components will likely need replacement but USACE will no longer need to excavate and replace the entire structure.

The next steps for the research group will be calibrating their model against the experimental results. This will allow the modeling techniques developed by Mr. Levine, Dr. Eick, and Dr. Spencer to be applied more generally for different types of anchorages in the USACE inventory.

Experiments were conducted in a loading frame filled with ~24 inches of ballast material. A track panel (half-crossties and rail) were placed on top of the ballast and vertical loads were applied to the rail at the center crosstie using a manual hydraulic jack reacting off of the top cross beam of the loading frame. Pressure gauges were placed in the ballast to record the crosstie-ballast interaction. Tests were performed in September 2020.

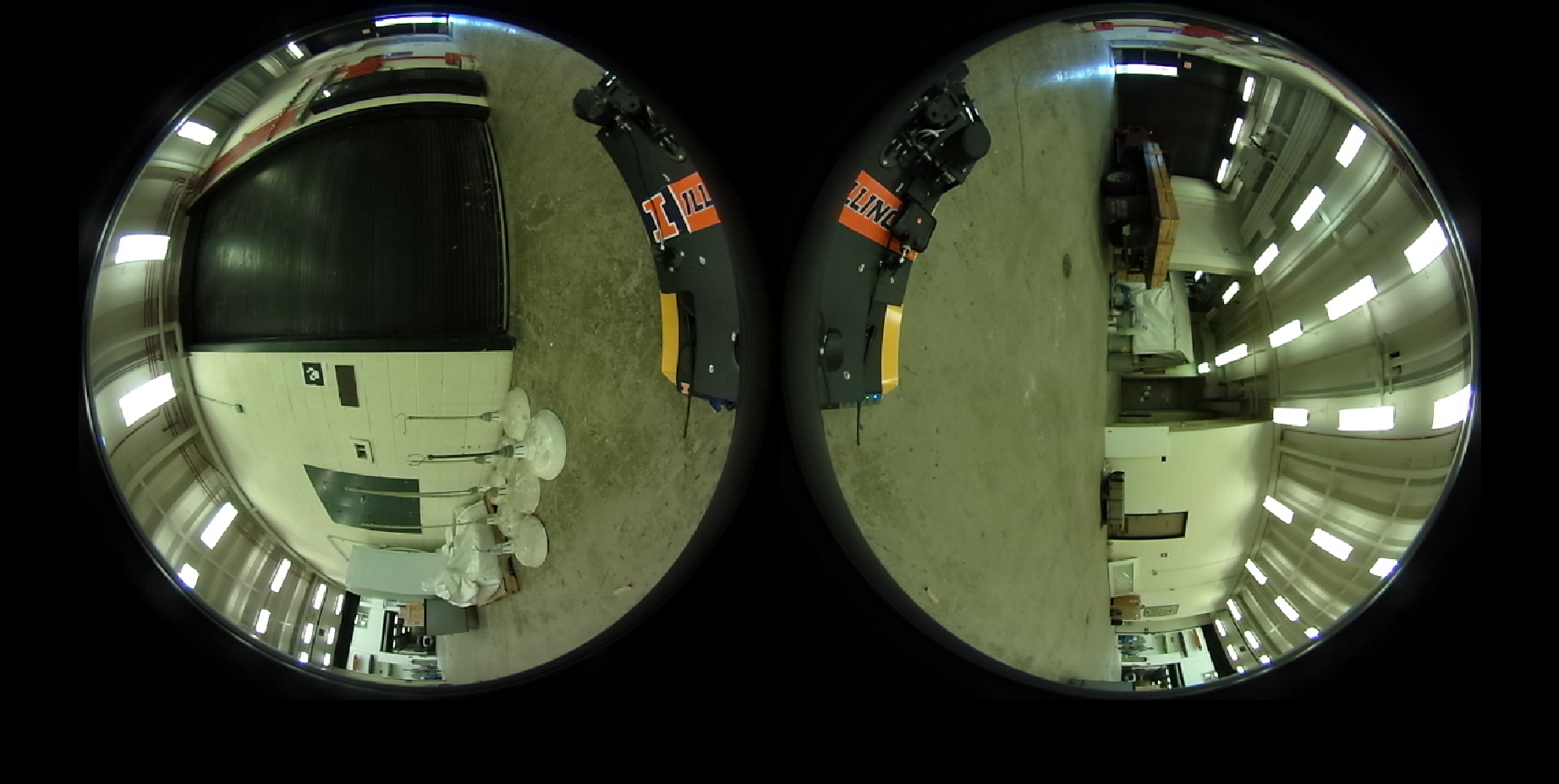

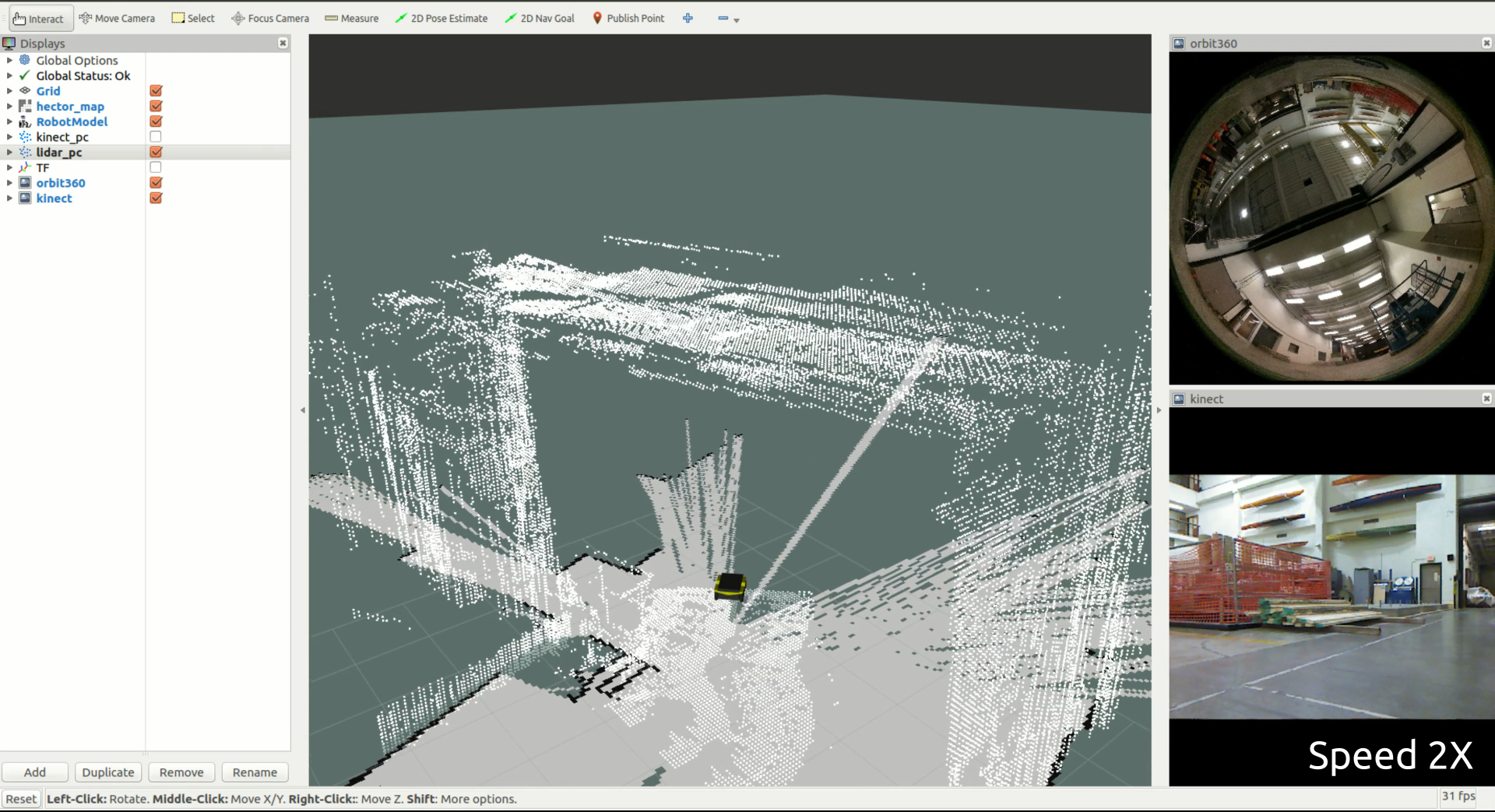

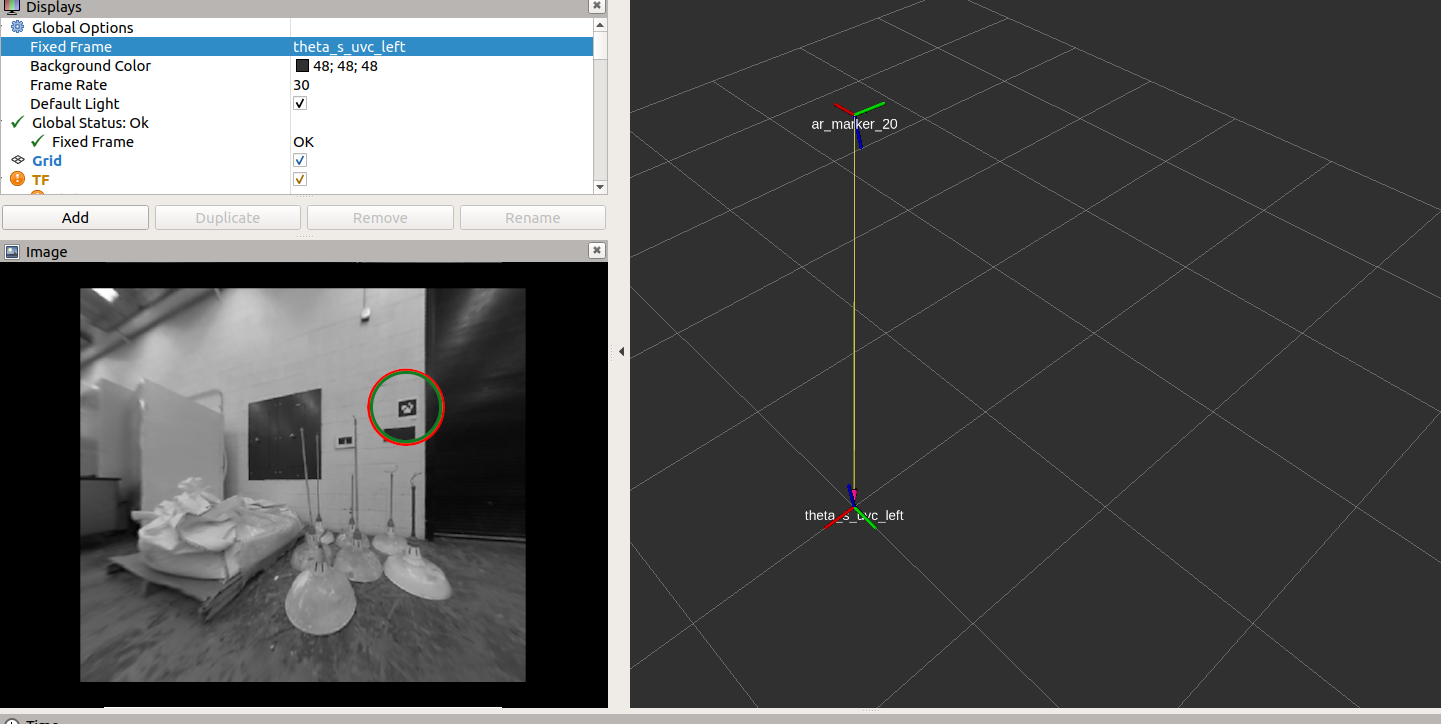

This research explores new path planning and navigation methods for autonomous robotic platforms that support reality capture on construction sites. New methods and metrics are developed that guarantee accuracy and completeness of reality mapping for construction progress and quality monitoring applications. Lab testing is used to validate the performance of these methods and metrics against simulated values.

For more information, please contact Amir Ibrahim (aaelsay2@illinois.edu) or Prof. Mani Golparvar-Fard (mgolpar@illinois.edu).

Bridges with various timber structural components make up a large portion of the transportation infrastructure in the US. Bridges supported on timber pile substructure, simply referred to as timber pile bridges, are particularly common. Many timber pile bridges still in service today were constructed in the 1950’s and 60’s using simplified design approaches largely based on convention and empirical data. Since only gravity loads were considered in their original design, many timber pile bridges are deficient by modern standards. Further exacerbating this problem is their age and the susceptibility to degradation. Despite these issues, timber bridges in general are overlooked in terms of operational importance and afforded minimal maintenance effort. Furthermore, whereas countless research studies have focused on every aspect of conventional reinforced concrete or steel bridges, research activity on timber bridges has been almost non-existent. Given ever increasing demands on bridges and interest in sustainable, resilient structures, the time is now to close the gap. This research is devoted to the experimental testing of timber piles with a special focus on the short- and long-term performance of piles retrofitted with fiber reinforced polymer (FRP) composites. The impact of timber deterioration and the effectiveness of different FRP application strategies are examined to make retrofit design recommendations, and a unique accelerated aging procedure is used to study their durability. Numerical approaches are used to develop methods for estimating the capacity of deteriorated timber pile bridge substructure. This includes a comprehensive load rating method for abutment timber piles in which the in-situ pile condition is a key input parameter. The findings from this research clearly demonstrate the need to more carefully consider the safety of existing timber bridges, and show that proper maintenance and retrofitting can significantly improve their strength and durability. Most importantly, this research contributes simple and robust tools for assessing the vulnerability of timber pile bridges under various loading conditions.

]]>For many years, steel has been used as the primary reinforcing material for concrete structures. Despite requisite stiffness, strength, ductility and desired deflection properties, steel reinforcing bars have tendency to incur permanent plastic deformations under excessive loading. Recently, fiber reinforced polymer (FRP) reinforcing bars have also been used in concrete structures to address corrosion issues typically associated with conventional steel bars. However, due to their linear elastic behavior, they are not considered in structures which require ductility and damping characteristics. The use of shape memory alloys (SMAs) with their nonlinear-elastic behavior in the composite could potentially provide solution for this problem. Small diameter super-elastic Nickel-Titanium (NiTi) SMA wires, coupled with polymer matrix is sought in this research as reinforcing bars in reinforced concrete (RC) moment resisting frames (MRFs) to improve the performance of the frames in terms of reducing residual inter-story drifts and damage under earthquake loading, while still maintaining the elastic characteristics associated with FRP. SMA fibers, conventional polymeric fibers and resin are infused together to manufacture the new composite under high pressure and temperature. Uni-axial cyclic tensile tests are carried out to characterize the mechanical hysteretic behavior of the new composite. Analytical constitutive models are developed for the SMA-based composite materials and calibrated based on experimental test results. These material models are then extended for use in structural models to capture the hysteretic behavior of the composite. Efficacy of proposed SMA-FRP composite reinforcement is further explored by embedding it in a small scale beam tested under 3-point bending.

]]>This project focused on developing an Adaptive Prestressing System (APS) for concrete crossties. The new prestressing system utilizes a unique characteristic of a class of smart materials known as Shape Memory Alloys (SMAs). Through heating, a SMA can recover its original shape after being excessively deformed beyond its elastic range. This shape memory phenomenon of SMAs can be used as a mean for prestressing concrete by embedding prestrained SMA wires in the concrete. When heated, the SMA will attempt to shrink inducing large recovery stress within the SMA that will in turn transfer to the surrounding concrete in the form of prestressing force. NiTiNb SMA were used in this study to prestress concrete crossties in the form of APS. APS can be described as a fuse made of SMA wires connected to steel wires in series. The APS is utilized to apply prestress only at target regions in the crosstie. The research work comprised three main phases: (1) validating local prestressing using SMA wires only, (2) developing the APS, and (3) structural testing of concrete crossties using APS. First, to validate the use of SMA as prestressing material in concrete, 2mm diameter NiTiNb SMA wires were used as prestressing reinforcement in small-scale 30 in. long concrete crosstie specimens. Three small scale concrete crosstie specimens were designed with different SMA prestressing system configurations, namely, straight, L-shaped, and U-shaped. Digital Image Correlation (DIC) and strain gauges were used to capture strain distribution within the ties during prestressing. The test results showed that SMA was able to apply prestressing force locally in the crossties at the intended locations. The second phase of the project focused on the design and development of APS for crosstie prestressing. An APS consists of steel and SMA wires connected mechanically in series to act as a prestressing reinforcement in the tie. When the SMA wire in the APS (named fuse) is activated, i.e. heated, recovery stress generates in SMA transferring through the connection to the steel wires. In this application, SMA fuse is used as mechanism through which steel wires are easily stressed without the need for conventional hydraulic jacking/stressing. To validate the new concept, a 1/2-scale concrete crosstie prestressed with the new APS was tested. The tests proved the success of the proposed APS in applying prestress to a targeted region in the crosstie.

]]>Self-consolidating concrete (SCC) is a workable yet stable concrete which flows easily and consolidates under its own weight. Its unique properties can substantially reduce the labor required to pour complex or heavily reinforced structural members. Over the past decade, the American precast industry has taken significant strides to adopt SCC in commercial projects, though concern about early-age bond behavior has limited the material’s application in prestressed members. A keen understanding of SCC’s bond strength, including its impact on transfer and development lengths in prestressed members, is essential to safely implement SCC in prestressed design. The Illinois Department of Transportation (IDOT) has sponsored a three-phase study exploring the bond behavior of steel strands in prestressed bridge girders. In the first phase, 56 pullout tests were conducted to compare the performance of seven-wire strands embedded in SCC and conventionally-consolidated concrete blocks. In the second phase, transfer lengths of prestressing strands in two SCC hollow box girders and two SCC I-girders were determined experimentally. In the third phase, the development length of strands in the two box girders was determined through a series of iterative flexural tests. This thesis details the three phases of the IDOT study and compares results to industry standards and requirements of the American Concrete Institute and the American Association of State Highway Transportation Officials. Results are also compared to analytical methods proposed in the literature. Additionally, a systematic method is developed to predict transfer lengths in full-scale specimens using pullout test data and finite element analysis. The proposed method may be useful when large-scale testing is impractical in terms of time or cost.

]]>Concrete bridges play an important role in the transportation network. However, there are more than 56,000 bridges that have been identified as structurally deficient in the U.S., especially those bridges located in the Northern part of the U.S. where harsh climate inflicts severe damage to the structural integrity and durability of the bridges. Among all types of damage, the distressing of end regions in bridge girders is very commonly observed. This damage could be in the form of cracking and spalling of concrete and steel corrosion. This research focuses on addressing this type of damage through innovative repair methods using fiber reinforced polymers (FRP). FRP has attracted researchers’ attention because of its high strength-to-weight ratio and corrosion resistance. However, the benefits and effectiveness of repairing concrete girders with damaged ends using FRP, especially if the damaged region is localized at the end (i.e. under very short shear span) have not been studied in depth yet. This research utilizes experimental and numerical approaches to explore the effectiveness of using FRP laminates to repair and strengthen concrete girders with damaged ends. Since the specific damage described above is mainly localized at end regions of precast pre-stressed concrete (PPC) girders where beam theory is no longer applicable, the behavior of end region (D-region) repaired/strengthened with FRP is studied using strut-and-tie model (STM). The research tasks carried out comprises conducting three-point-bending tests on full-scale PPC girders repaired with FRP laminates. Finite Element Analysis (FEA) and parametric studies are also performed on PPC bridge girders to explore the effect from various repair designs on the capacity and ductility of the PPC girders using both FRP laminate. The results from parametric studies are used to generate and calibrate the STM, which is adopted to analyze the shear capacity of PPC girders repaired with FRP laminate.

]]>This research focuses on examining the use of shape memory alloy (SMA) spirals in the seismic retrofitting and repair of reinforced concrete (RC) bridge columns. The thermally triggered recovery stress of pre-strained SMA spirals is utilized to apply large active confinement pressure at the column’s plastic hinge zone to enhance the flexural ductility of vulnerable columns and limit their post-earthquake damage. Although research has proven that concrete active confinement is a more superior technique to passive confinement, its field application using conventional materials is hindered due to several complications related to the method of application. This research focuses on investigating the new concrete active confinement technique using SMA spirals numerically and experimentally, which is rapid, robust and simple. The research work comprises of: 1) Performing numerical analysis on RC columns retrofitted using SMA spirals (active confinement) and Fiber Reinforced Polymer (FRP) wraps (passive confinement) to examine the superiority of the suggested new confinement technique over current confinement techniques, 2) Investigating experimentally the thermo-mechanical behavior of NiTiNb SMA which is used for this research, 3) Testing concrete cylinders wrapped with SMA spirals and Glass-FRP (GFRP) wraps, 4) Conducting quasi-static lateral cyclic tests on four 1/3-scale RC columns retrofitted with SMA spirals and GFRP wraps, 5) Conducting quasi-static lateral cyclic tests on two severely damaged columns that were repaired using SMA spirals as an emergency repair technique, 6) Utilizing the experimental results of the tested columns to develop and validate numerical models for RC columns retrofitted with SMA spirals, and 7) Utilizing the validated models to conduct a comprehensive parametric study on columns retrofitted with SMA spirals. The results of this experimental and numerical work clearly illustrate that using thermally pre-stressed SMA spirals to apply external active confinement pressure on concrete columns is an effective, simple, robust, and rapid approach to improve the performance of RC bridge columns.

]]>